We Dig Adobe: The Making of Adobe Bricks

One of the first questions, and obviously a pertinent one, that I bump into when helping people with their Adobe Homes is, “how do you make the bricks.” So, in an effort to keep all the Adobe lovers out there informed, I thought I’d run through the ingredients and the process really quick.

The Weir Bros. Adobe bricks were made up of a few simple ingredients…

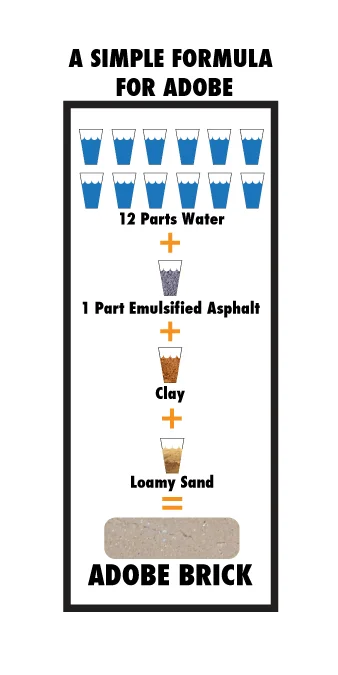

Either on site, or in one of the brickyards, adobe artisans would create a base mixture of:

1 Part Emulsified Asphalt & 12 Parts Water

They would then add a mixture of Loamy sand and clay to the base until they achieved a solid enough consistency to sit in the form without running.

Quick explanation on Loamy Sand and Clay: Most people think that Adobe bricks are comprised solely of clay, but it is actually a mixture of the two components and emulsified asphalt that gives them the stability to withstand the elements. Loamy sand was the ideal component for adobe bricks as it is readily found all over the Southern California Region, i.e. Escondido, Pauma Valley, Valley Center, Rancho Santa Fe, Encinitas, Cardiff, the list goes on. The right mixture of the two is extremely important as with too much sand, bricks would crumble, and with too much clay, bricks would crack as they shrink. The emulsified asphalt makes the bricks water resistant (no other water or weather treatments are recommended, they do not interact well with the emulsified asphalt and cause increased degradation.)

Diesel oil would be spread on the perimeter of the Adobe Brick forms to prevent the edges of the bricks from sticking to the form when the bricks were being removed.

-Rob Weir